|

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| Code 726

H equals Beige-Grey ( H stands for the paint supplier at the time,

Herberts) |

| |

|

|

|

|

|

| |

All numbers

match. |

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

| Very unusual

virginal trunk floor. Typically even dry California cars have surface

rust here. |

|

|

With our Motoring Investments inspection report now completed, we

begin the restoration. It is imperative to begin the

restoration process with the most solid example you can find. Below are

some photographs documenting

the

extensive restoration this car is undergoing.

|

|

|

|

| |

|

|

|

The picture

to the left is of the rare

and still present, seat belt hook.

The image to the right is of the

original color coordinated threshold sill

pad. Notice that it is beige. (M-B only

supplies new replacements in black).

We may have to be creative here. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

These photos

are of the engine stripped

down to the bare block. All parts

are removed, catalogued, inspected, and

replaced or reconditioned to look

and function as new. |

|

| |

|

|

|

The photos to

the left and right are

of the transmission tunnel area with the

transmission out of the car. The

transmission will also undergo a

complete and detailed restoration,

both mechanical and cosmetic. |

|

| |

|

|

|

|

|

| |

The above picture shows the exhaust

manifolds

before being sent out for coating.

We have them coated in a high grade aerospace

ceramic finish. This process lowers the

temperature in the engine bay and extends the life of neighboring

components.

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

The images

above are

of all the hardware, fuel lines, and fasteners

being sent out to undergo a

cleaning and re-plating process. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

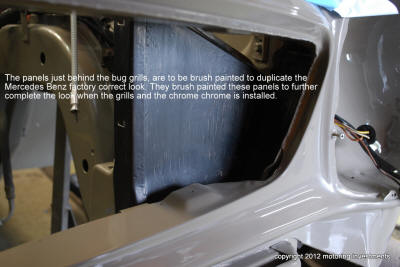

These

pictures to the left and right

display the tape that Mercedes Benz factory

technicians used to protect the body

and bug grills from rubs and rattles.

As per Motoring Investments' standards,

we will duplicate every detail the

factory technicians completed over 40 years ago. |

|

| |

|

|

|

|

|

| |

|

|

|

We carefully

removed the original firewall

pad. |

|

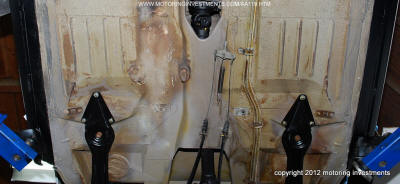

The undercarriage pictures below show the

rust free state of the car. We remove all suspension components and

rebuild the entire car.

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

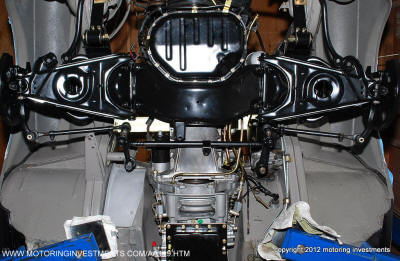

The pictures

shown here are

with the front

suspension in place, below we have

photos of the front suspension and

rear

end components

removed from the car.

These pictures are key to completing

a full inspection of the undercarriage and all

aspects of the rebuild can be addressed. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

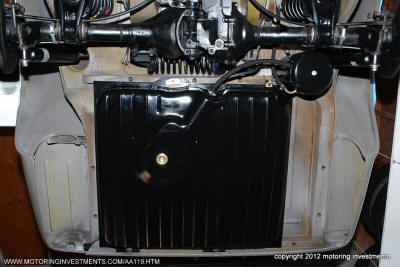

Below, the

fuel tank is removed. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

Before the powder coating

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

After the powder coating is completed

|

|

|

|

| |

The pictures

below, left and right

show the wheels and valves.

The correct air valve is taller than

the standard version to allow for

clearance from scratches

as you check and fill your tire pressure.

|

|

|

|

|

| |

|

|

|

The pictures

above and below are of the wheelhouse partition panels. These panels are often

susceptible to

corrosion. They arrive from Mercedes Benz in a satin black finish with

no undercoating applied. We spray them

and paint them body color to match. |

|

|

| |

|

|

|

The rear end

will be removed.

Completely serviced and any

issues will be addressed.

The pictures on the right show the

bottom side of the trunk floor. Removing the

gas tank facilitates inspection and allows for

proper restoration of all components. |

|

|

|

| |

|

|

|

|

|

| |

Notice the trunk floor and its condition.

This area is often prone to corrosion.

Even dry climate cars are known

to have light surface rust

from condensation improperly evaporating.

This trunk floor is in great condition.

|

|

|

|

|

| |

The dash disassembly is

documented and parts are meticulously

inspected.

|

|

|

|

|

| |

The

photographs above are of the door

threshold trim and pads. Notice the rare

color coded threshold sill pads?

Completely original and correct for this car.

|

|

|

|

|

The above row displays pictures

of the interior and dash disassembly.

All switches, knobs, levers and electrical connections

are inspected, documented and reconditioned for serviceability.

|

|

|

|

Removing all

the chrome trim, uncovers

more traces of the original gray-beige paint underneath. |

|

|

|

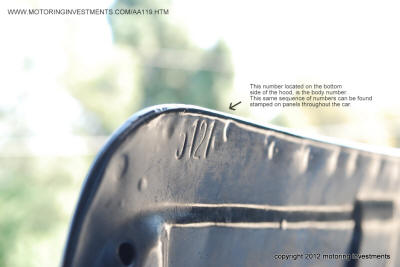

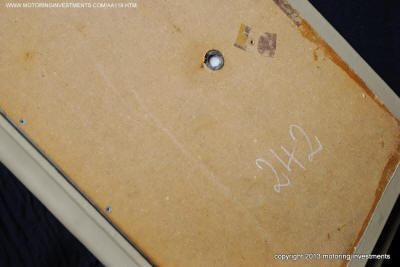

The number above is the

body number.

This sequence corresponds with all the

numbered panels on the car,

proving a body panels

(numbers matching) car. |

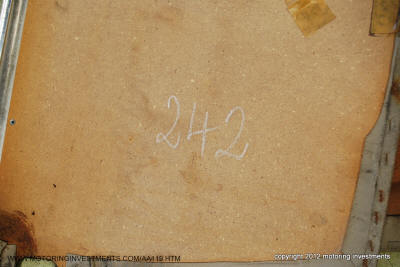

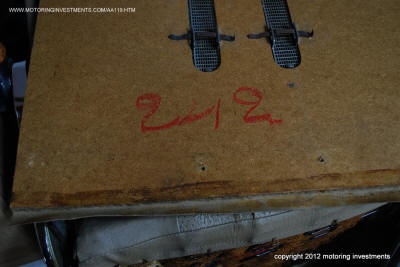

The # 242 is the

production number.

Notice all the interior panels are identified

with the same number. Door panels,

glove box, dash pieces and seats all

match. |

The underside of the

folding top compartment shows

the satin black original paint. |

|

|

|

| The backsides of the door

panels. |

|

The photo below is of the

backside of the seat back panel. |

|

Original

paint color code # 726 (Beige Grey)

Original color code for hard top # 726 (Beige Grey)

The data plate on the inner fender also displays

the production number ( #..242)

and the body number (#..121) |

|

|

|

|

The production number

listed on the

inside of the seat frame. |

|

Close up picture

of the seat frame. |

|

|

|

| |

Here are the "before" pictures of the wood.

It is carefully removed and veneered,

and refinished

to match the original color.

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

The pictures

above show the interior during

disassembly. Notice the waffle pattern floor

insulation in the photo above. This padding is

factory correct and was installed as an insulation

or sound deadening material.

The pictures above

also display the interior floor boards and their

exceptional and original condition. |

|

| |

|

|

|

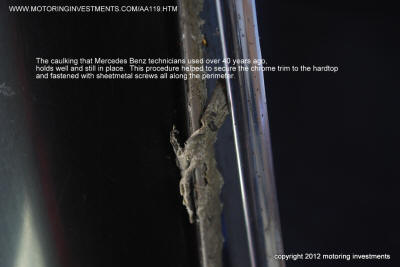

The caulking

applied by the

factory technicians, still in place for

over 43 years.

|

|

| |

|

|

|

|

|

| |

|

|

|

The headliner

in the before state. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

The pictures above show the old headliner foam that disintegrates over

time.

And below are images of the new foam going in place after the hardtop is

stripped and

cleaned.

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

The new

headliner.

The picture below is a close up of the hard top

rear shelf area with the # 726

marked with a wax pencil from the factory.

This number corresponds with the color code. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

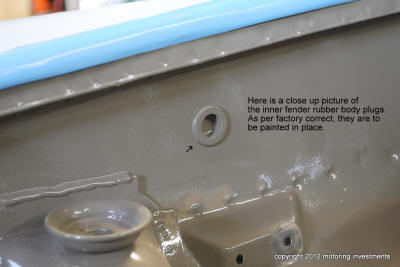

The pictures above and below show us

the engine bay after the paint process.

Also notice the picture above of the

inner fender plugs painted in place.

|

|

|

|

| |

|

|

|

|

|

| |

The headlamp

bucket

pictured above is shown with the ground points

protected from the new paint. |

The wheel house

pictured below is painted

with the new partition panels.

|

|

|

|

| |

|

|

|

The

transmission mounting plate

is pictured to the left. This

plate is also a numbers matching panel

and painted to match the body color.

The fresh air flap

is pictured to the right. This

area is completely disassembled, painted,

and cleaned. Then reassembled with a

new cabin fresh air filter and all

new seals. The heater valve and O-rings

are also serviced at that time.

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

The gold and silver cadmium pieces

are catalogued and re-plated.

Upon completion the pieces are

sorted and re-building can begin.

|

|

|

|

|

| |

|

|

_small.JPG) |

New firewall

pad looks just like the original

pad from over 40 years ago. |

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

| |

The new

firewall grommets

to be installed. |

|

|

|

|

| |

Below are

pictures

of the engine bay components, after

the refinishing process. |

|

|

|

|

| |

|

|

|

|

|

| |

The parts are ready for installation. These

parts have been cleaned

tumbled with a ceramic

media to achieve the correct finish.

|

|

|

|

|

| |

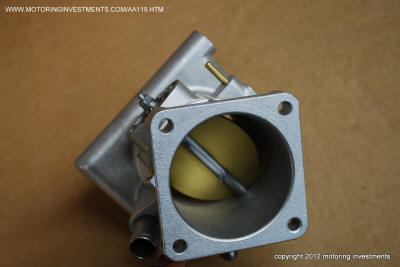

Valve cover,

throttle body, brake booster

pedestal, accelerator linkage

and bases. Everything is redone. |

|

|

|

|

The pictures below are of the front suspension being assembled after we

sand blasted and powder coated to match the factory satin black.

|

|

|

|

| |

|

|

|

The

surrounding pictures are of

the front suspension during the

rebuilding process. |

|

| |

|

|

|

|

| |

|

|

|

The view of the cylinder head and newly

coated

exhaust manifolds.

|

The picture

above is with the

valve cover and intake manifold

in place. |

|

|

| |

|

|

|

| |

The picture

below shows the engine mated to the freshly

rebuilt transmission. |

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

The picture

to the left and right are some examples

of the chrome before it is

stripped and re-plated.

The pictures below are of the exterior

and interior chrome after the

re-plating process is completed.

|

|

| |

|

|

|

|

|

Pictured

above is

the new side rear view mirror from Mercedes. |

The ashtray bezel

is carefully

removed and re-plated to look like new. During reassembly

the tabs must he heated and bent back very slowly to avoid the

risk of breaking the delicate fasteners. |

|

|

| |

|

|

|

The new trunk star and the new combination switch.

The switch controls the windshield wipers, turn signals and washer jets

as well.

These switches often need replacement from decades of use.

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

The gauges, top and

bottom.

Before installation and after....

flawless fit. |

All the instrument gauges are

serviced and fitted with new chrome bezels

along with new gauge seals

for an impeccable fit to the dash.

|

The picture below

is a close up of the reconditioned

clock. |

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

The original

Kangol seat belts

are also restored to look like new.

They will be re-webbed and the

chrome is re-plated

to look and feel fresh.

We duplicate every detail, from

re-applying the new decals on the buckles

to re-stitching the original labels. |

|

| |

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

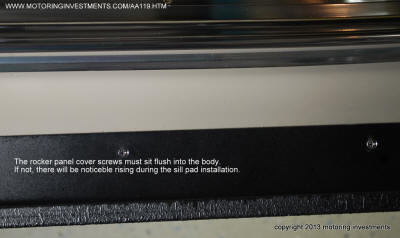

The pictures to the left and right

display the sheet metal screws

installed into the rocker panel covers. The

hardware is replaced with new fasteners. |

|

The pictures below are of the reconditioned

clock and dash going together.

|

| |

|

|

|

|

| |

|

|

|

|

|

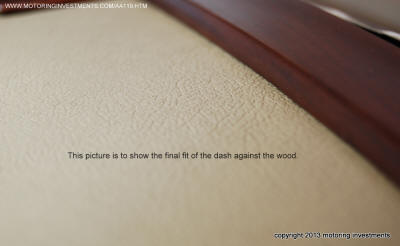

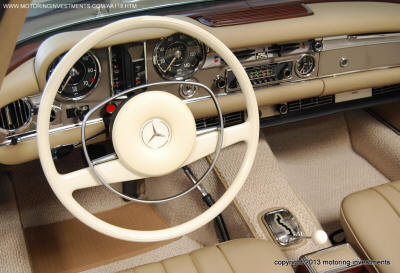

The pictures above and below show us the

progression on the topside of the dash.

The wood has also been restored and re-finished to the factory correct

look.

Below, we have pictures of the chrome being installed. Notice the

A-pillar chrome trims and the screws. They

must sit flush into the body and not protrude out from there respective

spot.

|

|

|

|

The pictures above and

below display

the exact fit the restoration is following.

All chrome, screws, wood, dash panels, etc.

fit perfectly. |

|

Another close up

view of the screws. To fit

like factory, a lot of

care goes into installing the fasteners. |

|

|

|

The pictures below are of the interior just

before carpet and interior panels installation. We duplicate the

satin black paint on the seat pedestals. The factory did this to hide

the

body color in the cockpit.

|

|

|

|

| |

|

|

|

All new

weather seals, temperature levers,

and body seals.

All OEM Mercedes Benz

seals and parts to insure of a proper fit. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

The oval speaker from the topside of the

dash is replaced with a new one.

|

| Re-trimming

the rear ledge of the hardtop |

|

|

| |

|

|

|

| |

|

|

_small.JPG) |

_small.JPG) |

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

The undercarriage pictures below show the

exhaust parts as well as hanging the

system in place.

|

|

|

|

| |

|

|

|

The photos to

the

left display the exhaust manifolds

before being sent out for coating. The photo

on the right shows the manifolds

coated in a high grade aerospace

ceramic finish. This process lowers the

temperature in the engine bay and extends the life of neighboring

components. |

|

| |

|

|

|

The pictures above and below are of the

exhaust system parts. The exhaust system is

first hung in place then removed to be

welded together for an exact fit.

The underside heat shield

(pictured on the left) that protects the

floor from the

exhaust temperature is in place.

|

|

| |

|

|

_small.JPG) |

|

_small.JPG) |

| |

All OEM factory

correct replacement parts. |

|

_small.JPG) |

_small.JPG) |

|

| |

Notice the lines of the exhaust pipes and

their relationship to the rest of the

undercarriage. A perfect fit.

|

|

|

|

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

The pictures above are of the front brake

discs and calipers.

The photos below show us the rear brake discs, calipers and wheel wells.

|

|

|

| |

The picture below shows us the rear deck

lid in the completed state.

|

|

|

|

|

| |

|

|

|

|

The pictures above display the chrome body moldings. These are re-plated

and installed

with all new screws and hardware. Notice the picture below, the screws

sit

flush into the chrome trim. The rubber profile, next to be installed, will now

sit flush into the trim channel.

|

|

|

| |

|

|

|

The photos to

the left and right are

of the bug grills, before we refinished

them. |

|

| |

|

|

|

|

|

| |

The photos above are of the bug grills refinished

and installed into the car.

|

|

|

|

|

| |

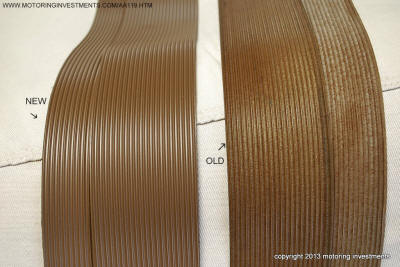

The

surrounding photos are of the door

threshold trim sets, both new and old. |

|

|

|

|

| |

|

|

|

|

|

| Spacer washers behind the

trim |

When preparing the trims for installation

we carefully remove the washers behind

the original outer trims. Their

purpose is to provide spacing from the

body to the

rocker panel covers.

|

The above picture is a

close up of a new trim with washer

in place along with

an old trim. |

| |

|

|

|

|

|

| |

|

|

|

The caulking

applied to the chrome

for the hard top needs to be spread evenly

and once installed, remove any excess.

The caulking assures a snug fit and proper

protection against the elements. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

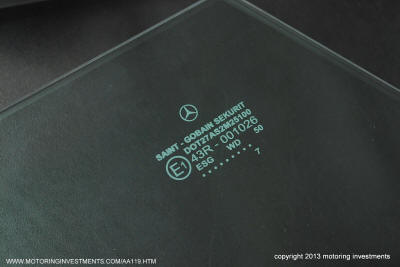

The body number

is also stamped on the bottom edge of the

hard top quarter window.

|

|

|

|

|

| The picture

above show the molding just installed, notice the space? |

|

|

| |

The pictures above show the moldings with their

respective joiner clips in place.

These clips finish the trim assembly

process to give the chrome a seamless look.

|

|

|

|

|

|

|

|

|

|

The photo above shows the precise fit. |

|

|

|

The picture above is displaying the chrome

trim installed and fitted with the rubber

profile along the inside of the glass.

This rubber profile helps centralize the

trim installation and seal up from any

outside elements. |

The photo displayed

below highlights the exterior trim

being installed onto the hard top. Notice the

chrome lip that has to sit flush

into position? |

Below is a close up

photo of the correct type of screws

to use while completing

the hard top chrome trim

installation.

Notice the flushness in

relation to the chrome and body?

They must fit perfectly

flush to the body and not stand

proud from the channel

itself. |

|

|

|

The pictures displayed above are of the hardtop quarter glass. These are

especially difficult to install.

Start the install of the glass and new seal at the bottom edge and work

up the glass to the topside.

Notice the protective layer we apply to help guard the

headliner while glass installation is taking place?

The seatbelt pictured below, are restored and ready for installation.

All buckles, decals, chrome, and

labels have been renewed or replaced.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

With no rear glass |

With the glass installed |

|

|

|

These pictures above show the rear chrome

trim being installed. |

|

|

|

The hard top handle bases are also re-plated

and feel like new. |

|

|

The photo above shows the hard top side

latches. These help secure the hard top onto the body. All

new hardware and washers are used to restore the latches. |

|

|

|

BEFORE |

AFTER |

|

|

The photos below show us the engine bay and its progression.

After testing and tuning, we apply the engine bay decals to finish the

complete restoration.

|

|

|

The photo below is of the

radiator to fan shroud

clip.

|

|

|

The pictures below are of the door mechanisms, fully reconditioned.

All window guides, glass blocks, regulator rods and rubber buffers

are inspected and serviced to function like new. When are doors are

completed, they

will sound and close just like when they left the factory, over 40 years

ago.

|

|

|

| |

|

|

|

|

|

The bumper backsides, shown

above and below. Notice the

gold cadmium plated bolts, bumpers brackets,

(refinished to match the correct black)

as well as the light color

used to refinish the backsides?

|

The photo above and below show the

bumpers' seamless look.

Notice they are not drilled with holes for the

cumbersome over riders.

|

The bumper

backsides are

painted to prevent corrosion and

display a finished, correct look. |

|

|

|

| |

|

|

|

|

The photos

above display the inner threshold trims and their respective matching

points. Notice the

screws and how flush they sit in the trim?

Proper alignment and installation of all the trim and rocker panel cover

screws will result

in a flush fit, thus having no imperfections when installing sill pads

and carpets.

|

|

|

| |

|

|

|

|

|

| |

The photo above shows the rubber

profile that goes into the chrome door trim. This

profile must be inserted and angle cut to fit correctly.

|

|

|

Notice the

pictures to the left and right are

of the profile being installed.

The photos below are of the

rubber profile in place and trimmed to fit. |

|

| |

|

|

|

| |

|

|

|

|

| |

Flawless

chrome grill. |

|

|

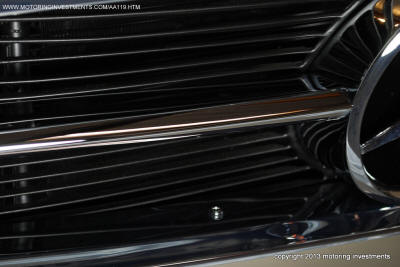

The photos to

the left and right

are of the

small

felt pieces that go affixed onto the

backside of the chrome grill center bars.

Often missing on even most high point

restorations, we produce

every detail, no matter how small

or inconspicuous. |

|

| |

|

|

|

|

|

| The front grill center

bar. |

The photos

above and below

highlight the perfect fit from nose to

grill. |

The protective tape that

is

applied to the bug grill

is visible from the backside, as per

factory original. |

|

|

|

| |

The photos

shown here, highlight the

impeccable finish of the newly

plated chrome, and its fit with the body.

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

The photo

above shows the correct

windshield wiper units. |

The correct screws that mates the fresh air

scoop to the body is also

gold cadmium plated.

Many times, these screws are incorrectly

painted over or not re-plated with

gold cadmium as per factory.

These screws should be easy to

remove, for a technician to be able to service the hoses

or mechanisms under the scoop.

|

|

|

|

| |

|

|

|

|

|

The photos

above are of the door threshold sill pads.

These are no longer available new in the original

colors.

As supplied by Mercedes they now only come in black.

We have refinished New OEM

door sill pads to match the correct and

original color code that this 280SL was born with.

Look closely at the new vs. old sill pads pictures above, the color is a

perfect match.

Pictured below are different angles of the door sill pads installed onto

the car.

|

|

|

| |

|

|

|

| |

|

|

|

|

|

The photos above are of the New Old Stock (N.O.S.) hood limiting strap.

The straps are labeled in the pictures and it is easy to see the

difference that 40+ years make in the engine bay. In the picture

above center,

note that the weave is a perfect match to that of the original item.

This item came from our "secret parts bin". What Mercedes typically supplies

today is a reproduction, that is pure white.

|

|

|

|

The

surrounding pictures

show us the mounting

plates on the hood and the new

hood limiting strap in place. |

|

| |

|

|

|

|

|

The photos above and below show the hard top in the finished state.

With nylon buffers installed to the locking latches and new screws and

cup washers on the

rear wood trim, the hard top is ready to go on the car. |

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

The images

above are of the glass

being adjusted to fit the

hard top. Then the soft top

frame is adjusted to the respective

glass position. |

|

|

|

|

| |

The photos

above and

below show the chrome trim and corners. |

|

|

|

|

| |

The hard top rests on the body with ease

and the picture above highlights the

clearance between the hard top and the body.

|

|

|

Here are

pictures of the seats before we disassemble

and rebuild them.

And the newly

restored seats are pictured below. |

|

| |

|

|

|

|

The door

panels are shown below, restored and covered with new material (note:

differences in lighting are

responsible for the drastic apparent difference in shade). |

|

|

The picture

below shows the just one of the many details that go into restoring a

car to this level. We obtained factory

correct and color matching eyelets to fit the seat backs where the head

rest rods pass through (made of "unobtainium"). |

| |

|

|

Below are

some close up pictures of the ashtray lid and its completed look. We

carefully

remove the bezel and have everything re-plated, followed by re-padding

and recovering the center. Assembly is very tricky with

the delicate tabs seen in the middle picture below. |

|

|

|

| |

|

|

|

|

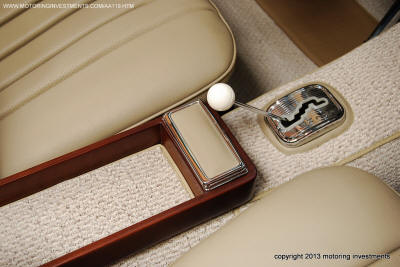

The new

Mercedes Benz ivory steering wheel and shifter knob are

ready to accept the horn ring and pad installation. |

|

|

| |

|

|

|

| |

|

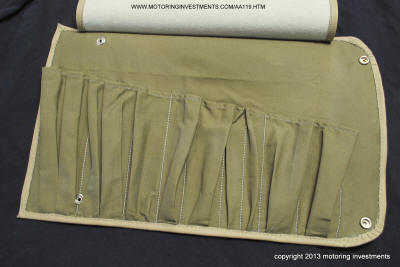

| Regarding tool bags,

the factory workman grabbed whatever bag happened to be on his tool bag

cart for the next car that came down the line. Sometimes a tool bag

happens to match a particular car's interior upholstery but this is

merely by chance. Most original 280SLs that I have experienced have had

a tool bag that differs from the upholstery color and material. The bags

were either M-B Tex or convertible top canvas.

In this case our client has opted for a bag that

matches his beige upholstery so we made one. |

|

|

| An original

tool bag shown above, was used this as a template. |

The finished

liner sitting atop the back of the beige M-B tex |

|

|

Every detail is duplicated right down to the snaps.

|

|

|

| |

after_small.JPG) |

|

The picture

above shows the

before and after tool bags. |

The tool bag

is completed with new

tools and fuse box below. |

|

|

| |

|

|

|

| The picture

above shows the correct number of fuses in the spare fuses box. |

|

|

| |

|

|

|

|

|

|

|

The photos

below on this column

represent the BEFORE condition of the trunk interior panels.

Made of a simple cardboard type material,

these panels often break or

become missing. |

Below here we

have pictures of

the newly acquired trunk panels for the

left and right sides. |

|

|

| |

|

|

|

Pictured

above are shots of the

panels before we replaced them.

The foam has disintegrated from over 40 years. |

Below is a

picture of the

NEW trunk panel and its backside shows

the foam padding. |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

The

trims at the windshield header bar are shown here.

These will be re-plated to look like new. |

|

|

In the images shown below, we have stripped all the previous plating and

revealed the brass metal underneath. We then polish the surface to a

smooth finish.

Followed by the re-plating with nickel to achieve the

factory correct look.

These trims, along with the horn ring, were finished in a dull

nickel/matte coating.

These parts were as such on US version cars, due to the strict D.O.T (

Department of Transportation) regulations

enacted. Mandating a non-reflective coating on parts that could

hinder/obstruct a drivers view.

|

|

|

| |

|

|

|

The correct

OEM folding

canvas top arrives from Mercedes Benz.

The Vehicle Data Card ( build sheet) reads as this car having a dark

brown canvas top. |

|

|

After we inspect the new canvas top for any imperfections,

We will begin installation of the new material to the folding top frame.

Mercedes Benz ships their folding canvas tops with the rear window piece

still hanging in place protected with tissue paper.

This helps to protect the rear window from shipping scuffs, creasing and

bending.

After installation is competed, the small threads will be cut out and

will reveal a scratch free, flawless

rear window.

|

|

|

We start by stripping the folding top frame of all materials.

After all folding top securing bolts are inspected and adjusted, we

remove strapping from bows. We clean the entire folding top frame from

old glue and any fabrics.

This assures a proper adherence for the new glue and new canvas

material.

|

|

|

| The header

bar is also rewrapped with new vinyl. |

|

|

| |

|

|

|

| Our expert

upholstery technician installing the OEM canvas top. |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

The weather seals for the folding top

installation are all pictured above.

We find that using the correct OEM (Original

Equipment Manufacturer) weather seals

provides for the best results. Non-OEM ( aftermarket) weather seals on the market today

do not fit correctly and are NOT molded to fit like the correct OEM

seals.

|

|

|

| The images of

the glove box area and remaining crash pads are shown above. |

|

|

The images shown above are of the wrapping under the fresh air vents.

The image on the left shows the wrapping and picture to the right, is

with the crash pad/knee bolster

in place.

|

|

|

| The images

above and below are highlighting the finished dash panels. |

|

|

| The pictures

above show the final fit of the wood to the dash, absolute perfection. |

|

|

| The photos

above and below highlight the engine bay in its current state. |

|

|

|

The firewall

lip to engine hood buffers are pictured above. Notice the lines on the

topside of the original buffers?

We have exact duplicates to replace the original buffers that are over

40 years old. |

|

|

| Valve Cover

decal |

Brake Booster

decal |

|

|

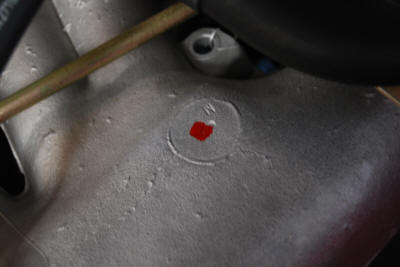

A dot of red paint

atop of the intake manifold.

This dot symbolizes our foreman has inspected, tuned and

all mechanical systems met factory standards.

Just like the lead technician

would have done over 40 years ago.

|

Correct decal

placed

atop the transmission dipstick. |

|

|

| The folding

top compartment instructions decal. |

The decals

are placed on water catch tank. |

|

|

| |

|

|

|

| |

|

|

| |

|

|

Notice the

restored seat belts and the date codes? Labeled

"date of manufacture 1968". We elevate

these cars to a level that the original factory technicians would be

proud of.

From correct dotology through out the car to date codes on seat belts,

every detail is duplicated and documented. |

|

|

| |

|

|

| The spare

tire casing or "cover" as it arrives from Germany. |

|

|

The

special compartment for the tire iron and wheel

installation alignment tool is shown above. |

|

|

The keys pictured below were ordered from the factory in Germany.

These keys were cut to V.D.C (Vehicle Data Card) specifications

and basically proves that the car has not

been subject to a door handle replacement, lost keys or a re-keyed

cylinder.

This is an original 3-key car,

meaning one key for ignition,

another key worked the doors and gas cap,

and lastly the glove box/trunk lock key. |

|

|

| |

|

|

|

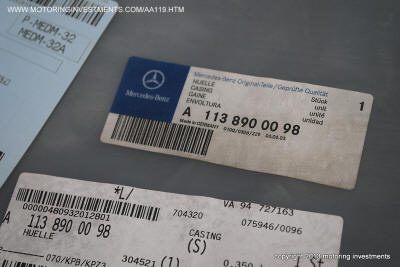

| New side

glass arrives from the factory. |

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|